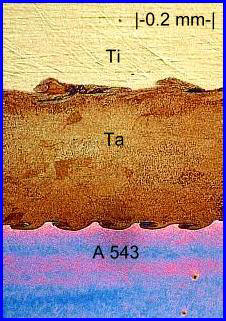

A customer application required plates of ASTM A543 steel, tantalum and titanium metallurgically bonded into a composite plate. This could only be done with an explosive shock wave.

The customer required images of the welded interfaces to demonstrate the integrity of the bonds. Images were also needed to evaluate and guide process improvements.

Metallurgical preparation required creating a totally new process. This was because conventional etching and polishing for each metal was not effective for the other metals in the sample.

This image is the result of a development of a unique set of mechanical-thermal-chemical polishing and etching processes. Areas of intensely cold worked titanium intermixed with cold worked tantalum are illustrated in the higher resolution image of the tantalum-titanium interface.

The micrographs satisfied the customer and helped guide improvements to the explosive welding process.